The PowerFlex 525 manual is a comprehensive guide designed to help users effectively operate and maintain the drive. It covers installation, configuration, and troubleshooting, ensuring optimal performance and safety.

Overview of the PowerFlex 525 Drive

The PowerFlex 525 is a high-performance variable frequency drive designed for efficient motor control. It offers adjustable speed regulation, compact design, and robust functionality, making it ideal for industrial applications. The drive supports a wide range of motors and provides precise control, ensuring optimal performance. With advanced technology and user-friendly interfaces, the PowerFlex 525 is a reliable solution for modern automation needs, offering flexibility, energy efficiency, and seamless integration with industrial systems.

Importance of the Manual for Users

The PowerFlex 525 manual is essential for users to unlock the drive’s full potential. It provides detailed instructions for installation, configuration, and troubleshooting, ensuring safe and efficient operation. The manual offers insights into parameter settings, safety precautions, and advanced features, helping users customize their experience. By following the guidelines, users can optimize performance, minimize downtime, and maintain compliance with safety standards, making it an indispensable resource for both novice and experienced operators.

Hardware and Software Features of the PowerFlex 525

The PowerFlex 525 combines robust hardware with advanced software capabilities, offering high-performance motor control, flexible configuration options, and seamless integration with industrial networks for efficient operation.

Key Hardware Components

The PowerFlex 525 features a compact design with essential hardware components, including an embedded EtherNet/IP adapter for industrial communication, versatile input/output modules, and a user-friendly control interface. The drive includes a high-performance motor control unit, power modules, and a robust cooling system to ensure reliable operation in various industrial environments. These components are designed to provide flexibility, scalability, and high efficiency, making the PowerFlex 525 suitable for a wide range of applications. Proper installation and configuration of these hardware elements are crucial for optimal performance.

Software Capabilities and Compatibility

The PowerFlex 525 supports advanced software capabilities, including Studio 5000 for programming and configuration. It is compatible with EtherNet/IP and other industrial networks, enabling seamless communication with Allen-Bradley controllers. The drive integrates with SCADA systems and offers parameter configuration through user-friendly interfaces. Software tools provide real-time monitoring, custom logic programming, and data collection. Compatibility with multiple protocols ensures versatility in industrial automation applications, enhancing productivity and system integration.

Installation and Setup Guidelines

Proper installation ensures optimal performance and safety. Prepare the site, follow safety protocols, and refer to the manual for step-by-step guidance and compliance with regulations;

Site Preparation and Safety Considerations

Proper site preparation is crucial for safe and efficient installation. Ensure the area is clean, dry, and well-ventilated. Verify power supply compatibility and ground the equipment correctly. Wear personal protective equipment, including gloves and safety glasses. Follow all safety labels and warnings on the device. Keep flammable materials away and avoid working in hazardous environments. Regularly inspect the system for damage or wear. Adhere to local electrical codes and manufacturer guidelines to minimize risks and ensure compliance with safety standards.

Step-by-Step Installation Process

Begin by unpacking and inspecting the PowerFlex 525 drive for any damage. Mount the unit securely on a flat surface, ensuring proper ventilation. Connect the power supply and motor cables according to the manual’s wiring diagram. Set the required parameters using the control panel or Studio 5000 software. Perform a test run to verify functionality. Ensure all connections are tight and connections are correctly configured. Refer to the manual for specific instructions on parameter settings and configuration.

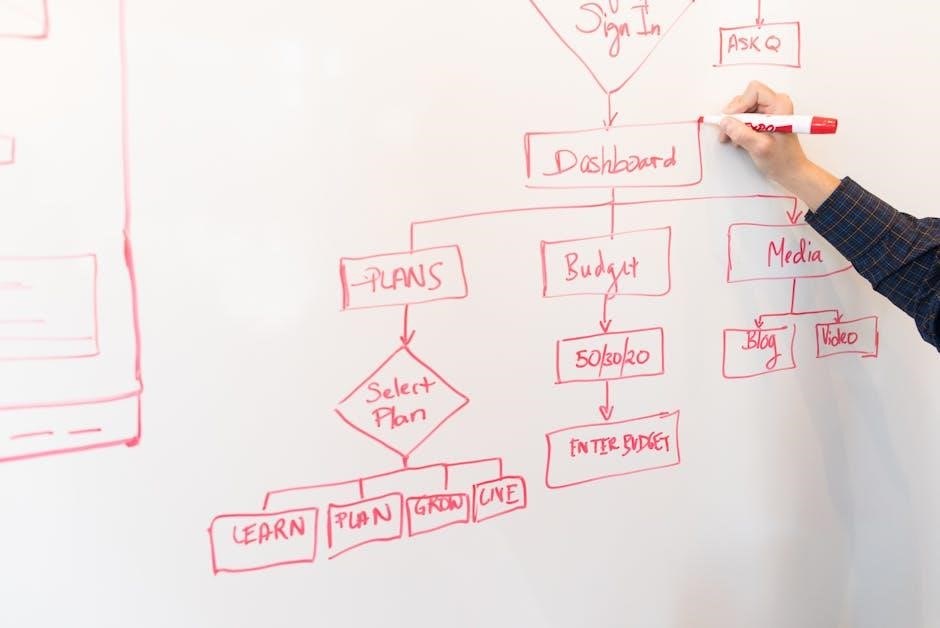

Configuration and Parameter Setting

Configure the PowerFlex 525 by adjusting parameters such as motor settings and control modes using the control panel or Studio 5000 software for optimal performance.

Understanding Parameter Settings

Parameter settings in the PowerFlex 525 are essential for customizing the drive’s operation. They allow users to define motor characteristics, control modes, and operational limits. Key parameters include speed, torque, and acceleration settings. Adjustments can be made via the control panel or Studio 5000 software. Proper configuration ensures optimal performance and safety. The manual provides detailed guidance on parameter functions and troubleshooting common issues. Always refer to the manual for specific instructions to avoid errors and ensure compliance with safety standards.

Configuring the Embedded EtherNet/IP Adapter

The PowerFlex 525’s embedded EtherNet/IP adapter enables seamless communication with industrial networks. Configuration can be done manually via the drive’s faceplate or using Studio 5000 software. Parameters such as IP address, subnet mask, and gateway must be set correctly for proper network integration. The adapter supports EtherNet/IP messaging, allowing real-time data exchange. Refer to the manual for detailed instructions on configuring network settings and troubleshooting connectivity issues. Proper setup ensures reliable communication and optimal performance in industrial automation systems.

Operating Modes and Control Methods

The PowerFlex 525 supports multiple operating modes, including Voltage/Frequency and vector control, offering precise motor control. Control methods include Start/Stop, Speed Reference, and advanced dynamic braking.

Different Operating Modes Explained

The PowerFlex 525 offers various operating modes tailored for specific applications. Voltage/Frequency mode is ideal for standard induction motors, providing straightforward speed control. Vector mode enhances torque control, suitable for high-performance applications. Flux observation mode optimizes energy efficiency, while the motor control mode ensures precise operation. Each mode is selectable through parameter settings, allowing users to customize drive behavior for their specific needs. Proper mode selection ensures optimal motor performance and system functionality.

Local Control vs. Remote Control

The PowerFlex 525 supports both local and remote control methods. Local control allows direct operation using the drive’s keypad or potentiometer, ideal for simple setups. Remote control enables operation via external devices or software, such as Studio 5000, offering advanced monitoring and configuration. Parameters can be adjusted locally or remotely, providing flexibility for different applications. Remote control is particularly useful for integrating the drive into larger industrial systems, while local control ensures easy access for basic operations and troubleshooting. This dual capability enhances user convenience and system adaptability.

Safety Precautions and Warnings

The manual emphasizes critical safety considerations, including proper grounding and voltage handling. Always follow labels and notes to ensure compliance with safety standards and prevent hazards.

General Safety Guidelines

Adhere to all safety precautions outlined in the PowerFlex 525 manual to ensure safe operation. Proper installation, grounding, and handling of high-voltage components are essential. Always wear protective gear and follow local regulations. Avoid unauthorized modifications and keep loose clothing away from moving parts. Regularly inspect equipment for damage and ensure compliance with safety standards. The manual highlights critical warnings and notes to maintain operator and equipment safety, preventing potential hazards and ensuring reliable performance. Always refer to the manual before performing any maintenance or adjustments.

Specific Warnings and Cautions

Adhere strictly to the PowerFlex 525 manual’s guidelines to prevent hazards. Never exceed the drive’s voltage or current ratings, and ensure proper grounding to avoid electric shock. Avoid unauthorized modifications, as they can lead to malfunctions. Always disconnect power before servicing and use appropriate personal protective equipment. Specific warnings include avoiding high-voltage terminal contact and ensuring proper ventilation to prevent overheating. Failure to comply may result in equipment damage or personal injury. The manual emphasizes these precautions to ensure safe and reliable operation of the drive.

Maintenance and Troubleshooting

Regularly inspect and clean the PowerFlex 525 drive to ensure optimal performance. Update firmware periodically and consult the manual for troubleshooting common issues efficiently.

Routine Maintenance Tasks

Regular maintenance is crucial for the PowerFlex 525 drive’s longevity and performance. Clean the unit to prevent dust buildup, which can cause overheating. Check all connections and cables for wear or damage. Update the firmware periodically to ensure compatibility and functionality. Inspect the cooling fans and heat sinks for proper operation. Refer to the manual for detailed guidelines on scheduled maintenance and diagnostic checks to prevent unexpected downtime. Always follow safety protocols during maintenance procedures.

Troubleshooting Common Issues

Troubleshooting the PowerFlex 525 involves identifying and addressing common issues like error codes, parameter misconfigurations, or communication faults. Refer to the manual for specific error code meanings and solutions. Check connections and power supply for stability. Use diagnostic tools like Studio 5000 to monitor drive performance and log faults. Ensure firmware is up-to-date, as outdated versions may cause compatibility issues. If problems persist, reset parameters to factory defaults or consult technical support. Regular maintenance can prevent many common issues from arising.

Integration with Industrial Networks

The PowerFlex 525 seamlessly integrates into industrial networks via its embedded EtherNet/IP adapter, enabling efficient communication and control. Studio 5000 software facilitates advanced configuration, ensuring optimal performance and connectivity with other devices.

Communicating with Other Devices

The PowerFlex 525 drive supports seamless communication with other industrial devices through its embedded EtherNet/IP adapter. This enables efficient data exchange and control within industrial networks. Users can configure the adapter using Studio 5000 software or directly through the drive’s interface. The adapter supports various industrial protocols, ensuring compatibility with a wide range of devices. Proper setup involves assigning IP addresses and configuring communication parameters to ensure reliable operation. This feature enhances integration and allows for centralized monitoring and control of the drive within industrial automation systems.

Using Studio 5000 for Advanced Configuration

Studio 5000 is a powerful software tool designed for advanced configuration of the PowerFlex 525 drive. It enables users to access and modify drive parameters, implement custom logic, and monitor performance. The software supports detailed parameter adjustments, allowing for precise control over the drive’s operation. Studio 5000 also facilitates communication with the PowerFlex 525 through its embedded EtherNet/IP adapter, enabling data collection and remote monitoring. By utilizing Studio 5000, users can create tailored automation solutions, enhancing the drive’s functionality and integration within industrial systems. Proper setup requires configuring the drive’s Ethernet address and ensuring compatibility with the software, which can be done manually via the faceplate or through the software interface. This tool is essential for maximizing the capabilities of the PowerFlex 525, providing a comprehensive platform for configuration, monitoring, and optimization.

Advanced Features and Customization

The PowerFlex 525 manual details advanced customization options, enabling users to unlock enhanced features like custom logic, monitoring, and data collection for tailored automation solutions.

Custom Logic and Programming

The PowerFlex 525 manual provides detailed guidance on implementing custom logic and programming, enabling users to tailor the drive’s behavior for specific applications. By utilizing Studio 5000 and embedded tools, users can create advanced control algorithms, define custom parameters, and optimize performance. The manual highlights how to integrate custom logic with EtherNet/IP communication, ensuring seamless interaction with industrial networks. This feature enhances automation capabilities, allowing for precise control and adaptability in complex industrial environments. Proper programming ensures safety, efficiency, and reliability in operation.

Monitoring and Data Collection

The PowerFlex 525 manual details methods for monitoring and data collection, enabling real-time tracking of drive performance. Users can access operational data, such as speed, torque, and temperature, through embedded tools or Studio 5000 software. This functionality allows for precise monitoring of motor and drive behavior, ensuring optimal performance and early detection of potential issues. Data logging capabilities support predictive maintenance, helping users identify trends and plan maintenance activities effectively. This feature enhances system reliability and operational efficiency in industrial applications.

The PowerFlex 525 manual serves as a valuable resource for mastering the drive’s features, ensuring safe and efficient operation. Refer to it regularly for optimal performance and troubleshooting.

Final Thoughts on the PowerFlex 525 Manual

The PowerFlex 525 manual is an essential tool for users, offering detailed guidance on installation, configuration, and troubleshooting. It ensures safe and efficient operation, helping users maximize the drive’s capabilities. By following the manual’s instructions, users can optimize performance, maintain safety standards, and resolve issues effectively. Regular reference to this manual is recommended for achieving the best results with the PowerFlex 525 drive.

Resources for Further Learning

For deeper understanding, refer to the PowerFlex 525 Embedded EtherNet/IP Adapter User Manual (publication 520COM-UM001) and explore Allen-Bradley’s official documentation. Utilize Studio 5000 software for advanced configuration and programming. Additionally, consult practical guides and tutorial videos available online, which demonstrate real-world applications and troubleshooting techniques. These resources provide comprehensive support for optimizing the use of the PowerFlex 525 drive in various industrial settings.

No Responses